ZMARTBUILD SPC Flooring

Compelling Comfort in Every Step

Go to section...

Pre-installation

Check all products for damaged, external defects before installation.

- Inspect the site of the work before the work is done thoroughly, the site must ensure the following criteria: The floor surface needs to be flat, not rough, smooth and clean, free of chemicals or garbage, especially dry. If the floor shows signs such as rough, cracked, then the first thing to do is to apply professional techniques to clean and flat the surface. Surface undulation should not be more then 5mm Per sqm.

2. In case of installation direction in the length of the room over 15m, must use T-sticks to divide the floor to create a space for the floor expanding during use. In addition, you can choose the horizontal installation of the room (with a horizontal condition of less than 15 m).

3. The position of the floor adjacent to the wall skirting, the skirting of the stairs, the staircase, the shelf or the fixed barrier is required to prevent the opening of the opening from 10-15 mm. Avoid spaces in all positions adjacent to the vertical and horizontal of the floor. The expanding gap will be covered by the wall skirting system, the end clamp. Remember to clean the open spacing, remove the agents that block the expansion of the floor, such as dust, stone, moss, etc.

4. During the construction of wall skirting, finish clamp, T clamp and other floor accessories… Note the use of suitable adhesives in sufficient quantity to adhesive. Avoid the case of cramps and fissures sticking dead onto the floor into a block leading to the floor not being expanded during use. Some suggestions when adhering to the floor accessories to ensure the expansion properties of the floor are as follows:

• For Wall skirting Apply the SR glue to the adjacent position to the wall skirting (as attached).

• For Finishing door reducers: Stick the glue into small dots, the gap between the dots is 30 – 50 cm with the case of L clamps, it is recommended to use the F clamp as a figure to ensure better quality.

5. Product case with no underlayment: You need an underlayment of 1.0mm to 2.0mm thick rubber, aiming to balance the floor, move smoothly and steadily. Do not use fresh rubber with a thickness of more than 2mm and PE foams with a gas foam inside.

Installation Instructions

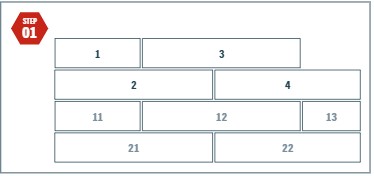

The product needs to be mounted with a parallel pattern; the parallel distance is half the plank as shown below.

1. The necessary tools include:

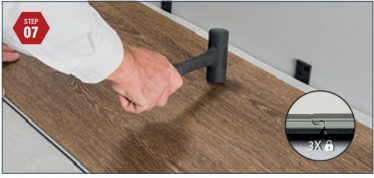

Wall seal tools, rubber and hammer tools, pencils, paper scissors, cutting machines.

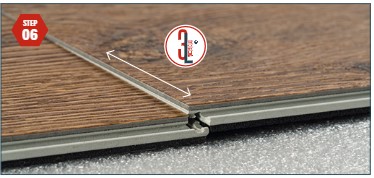

2. The floor installation process consists of the following steps:

Care & Maintenance

Regular Maintenance

1. Cleaning & Maintenance:

• Sweep the floor regularly with a soft bristle broom to remove loose dirt. vacuum on the correct hard surface setting can be used for daily maintenance.

• Mop the floor with non-abrasive, neutral PH floor cleaner. Do not use acidic floor cleaners.

• For everyday maintenance, a mop moistened with warm water will suffice.

• Spills should be cleaned up immediately.

2. DO NOT use the following on your ZMARTBUILD SPC flooring:

• Soap based detergents

• Abrasive or mop and shine products

• Floor wax

• Mineral oil or Rancid fluids

• Ammonia or bleaches*

• *For spot treatment, a diluted 10/1 solution of water/liquid bleach is tolerable for stain removal

• Vacuum cleaner with a rotating beater bar

Additional damage prevention and care

• To protect flooring from scratches, area rugs or mats are recommended, especially in exterior doorway areas to prevent gravel and dirt from tracking onto the floor.

• Use felt pad protectors on chairs and furniture to prevent scratches.

• Replace plastic or metal casters on chairs with rubber wheels and lift instead of sliding heavy objects across the floor.

• If there are stubborn residues or gunk that get on the flooring surface, use a mild dish detergent, and water mixture to spray onto the area. Quickly wipe up the sprayed area with a microfiber cloth/mop. Repeat this step as needed until the residue is clear and the surface is completely dry.

IMPORTANT: Never push, pull or drag furniture, appliances or other items across the floor. When moving furniture or heavy items, always lift and carry the items. Place hardboards between the flooring and object to move. Do not use Sharp objects to removal Paint, nail polish or other material

What is SPC Click Lock Flooring?

Refreshing your floor in 8 Hours!

Stone Plastic Composite (SPC) is a new concept to build a floor that has a real and natural look. SPC is durable and waterproof which makes it great for areas with high foot traffic e.g. living room, office, or even cafe & restaurant. It offers not only high performance, but also colours, styles and patterns that make your room cozy and a great place to live in.

Our SPC Flooring Benefits

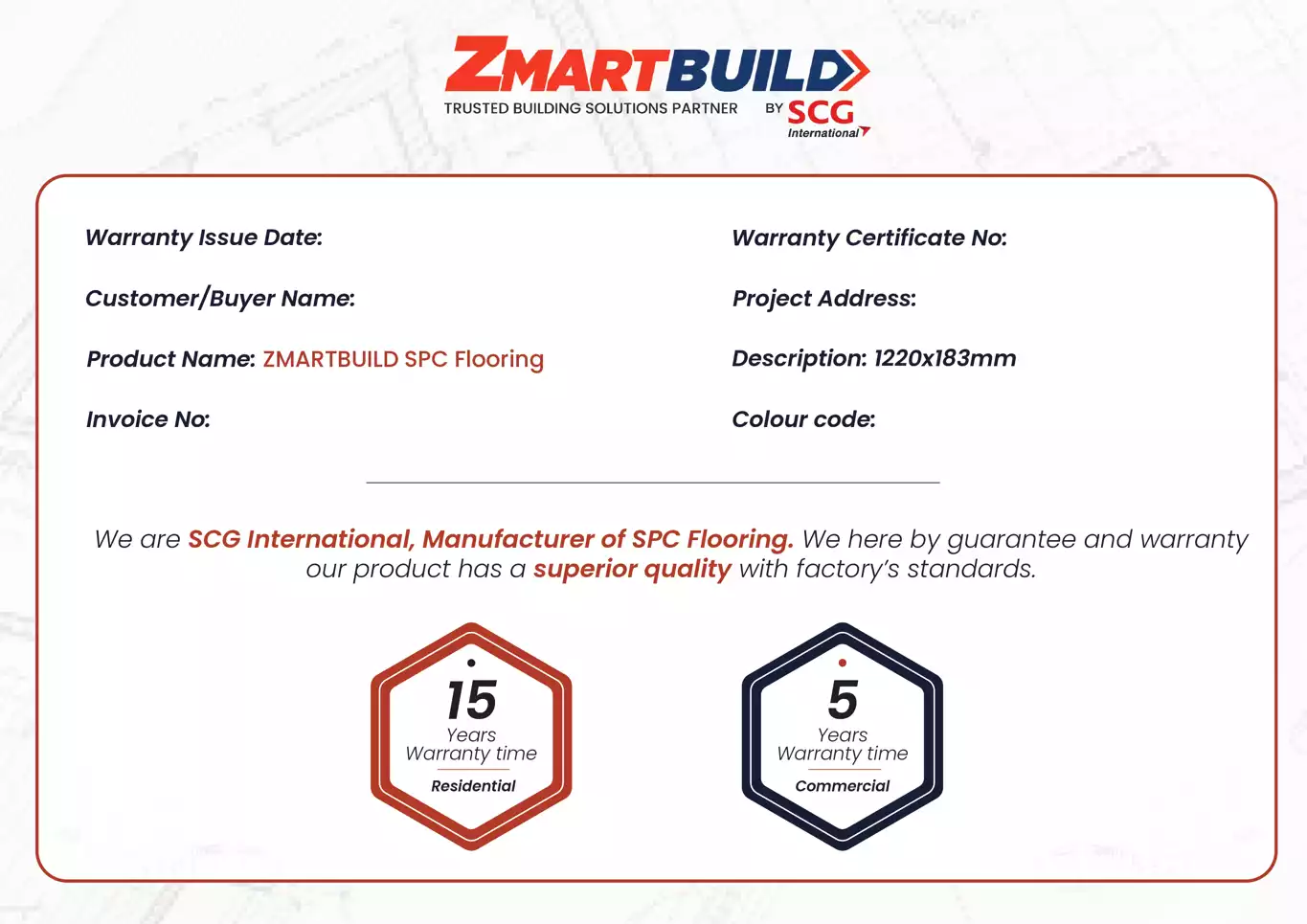

- Worry-Free, Warranty up to 15 Years

- Aqua Protect® High Quality Water Resistance

- Firm & Durable, Easy Maintenance

What is SPC Click Lock Flooring?

Refreshing your floor in 8 Hours !

Stone Plastic Composite (SPC) is a new concept to build a floor that has a real and natural look. SPC is durable and waterproof which makes it great for areas with high foot traffic e.g. living room, office, or even cafe & restaurant. It offers not only high performance, but also colours, styles and patterns that make your room cozy and a great place to live in.

Our SPC Flooring Benefits

- Worry-Free, Warranty up to 15 Years

- Aqua Protect® High Quality Water Resistance

- Create Beauty & Easy Maintenance

Installation & Advice

Get your new floor fast, only 8 Hours!

Just like “ONE STOP Service” for your Flooring, We can build your new floor in only 8 hours with ZMARTBUILD SPC Flooring. Let’s refresh your floor to be more natural touch & feel. ZMARTBUILD is one of the best Building Material Company In India. It’s SPC Tile is suitable for home, resort, hotel, restaurant or even office renovation & new build. It is superior durable scratch resistance, water resistance. Worry-Free from Start to Finish. Come; book your service today with India’s best SPC flooring manufacturer. Let our experienced ZMARTBUILD installers add aesthetics to your floor.