“In the previous chapter we explained the importance of BS5234 Part 2-1992 which helps to select the grading level of the partition in terms of breakage resistance and robustness. This shall be used to make a decision by the developer for selection of walls based on project requirements. For the BS 5234 Part 2 Partition Testing method of the partition, that we explained in last article. “

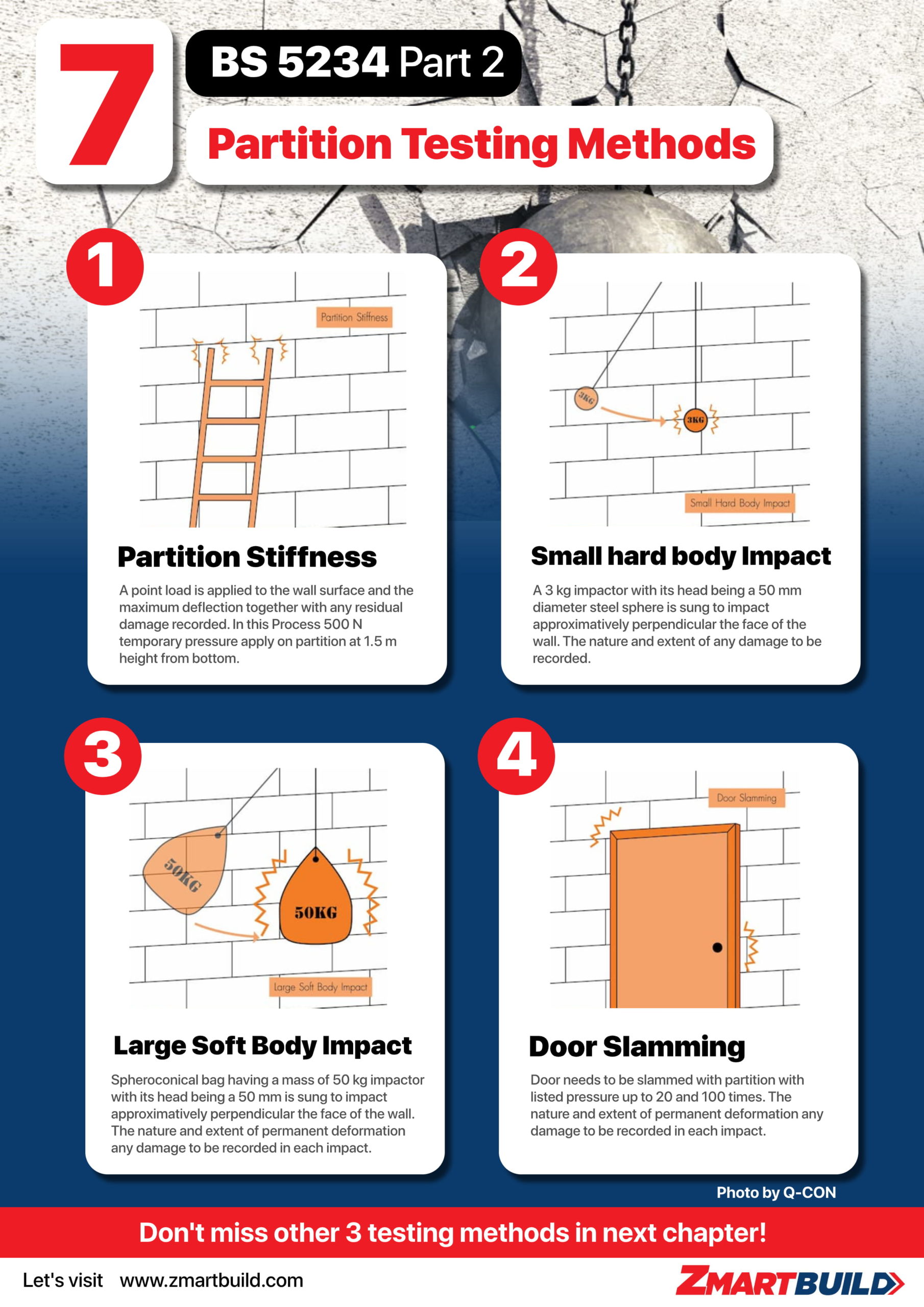

There are 7 testing methods which can be categorized into 2 groups of testing.

1. Breakage resistance of the BS 5234 Part 2 Partition Testing method which is enlisted as a major testing method .There are four types of the testing method which are considered for classification of the grade level depends on the breakage resistance of partitions.

2. The strength and the robustness testing method which is enlisted as a secondary testing method. There are three types of the testing methods which are considered for classification of strength and the robustness of partitions.

We will study the testing methods of first group in this chapter. Four tests are required to understand the breakage resistance of a wall partition as below.

Breakage resistance of the BS 5234 Part 2 Partition Testing method

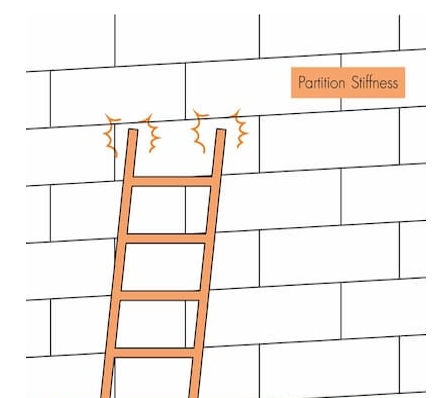

1) Partition Stiffness – The test is to establish the ability of the partition to withstand person or ladder leaning against it without causes unacceptable cracking or movement. To simulate this the partition is subjected to a static horizontal load at a set height and the maximum deflection and residual deflection or structure damage to be recorded on surface of wall.

Process – A point load is applied to the wall surface and the maximum deflection together with any residual damage recorded. In this Process 500 N temporary pressure apply on partition at 1.5 m height from bottom.

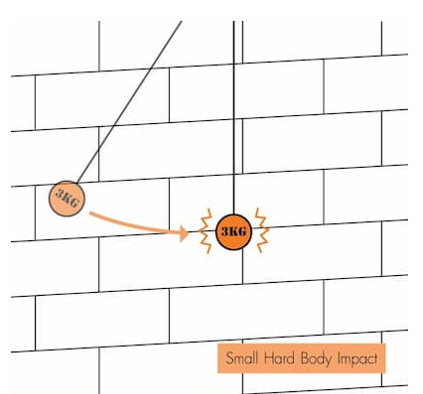

2) Small hard body Impact – The test is to establish the ability of the partition to withstand against damages with small hard object impacts. To simulate this the partition is subjected to a static small hard body impact at a set height and the maximum surface damage and residual deflection or structure damage to be recorded on surface of wall.

Process – A 3 kg impactor with its head being a 50 mm diameter steel sphere is sung to impact approximatively perpendicular the face of the wall. The nature and extent of any damage to be recorded.

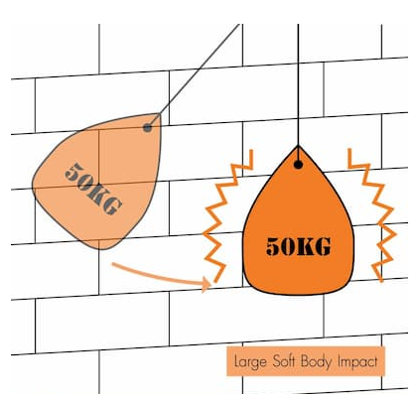

3) Large Soft Body Impact – The test is to establish the ability of the partition to withstand against damages with large soft object impacts. To simulate this the partition is subjected to two separate impacts from a soft body impactor impact at a set height and the maximum permanent deformation or surface damage or structure damage to be recorded on wall.

Process – Spheroconical bag having a mass of 50 kg impactor with its head being a 50 mm is sung to impact approximatively perpendicular the face of the wall. The nature and extent of permanent deformation any damage to be recorded in each impact.

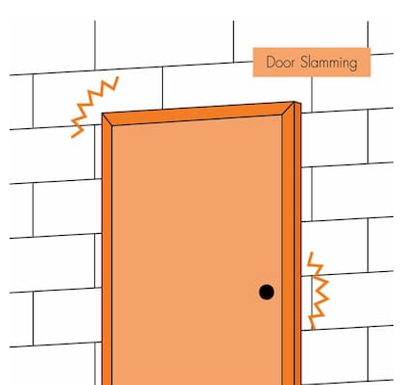

4) Door Slamming – The test is to establish the ability of the partition to withstand against impacts which are transmitted through the door frame to partition due slamming of door leaf. The residual displacement of the door frame to be recorded including any damage of the partition.

Process – Door needs to be slammed with partition with listed pressure up to 20 and 100 times. The nature and extent of permanent deformation any damage to be recorded in each impact.

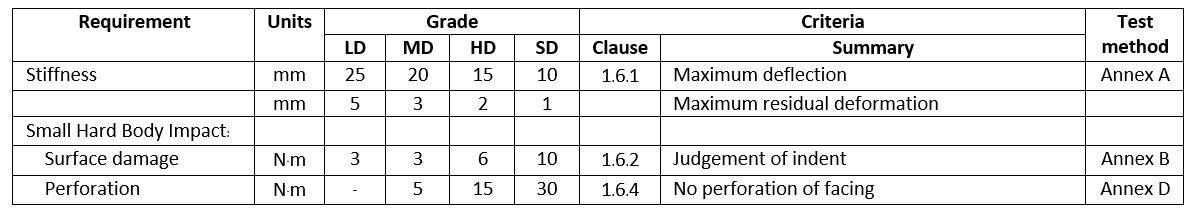

The BS 5234 Part 2 Partition Testing standards for each grading level are shown below.

Once you understand the result of all testing methods required for grading level of the partition, you can compare it with the testing reports of wall products given by each suppliers or manufacturers.

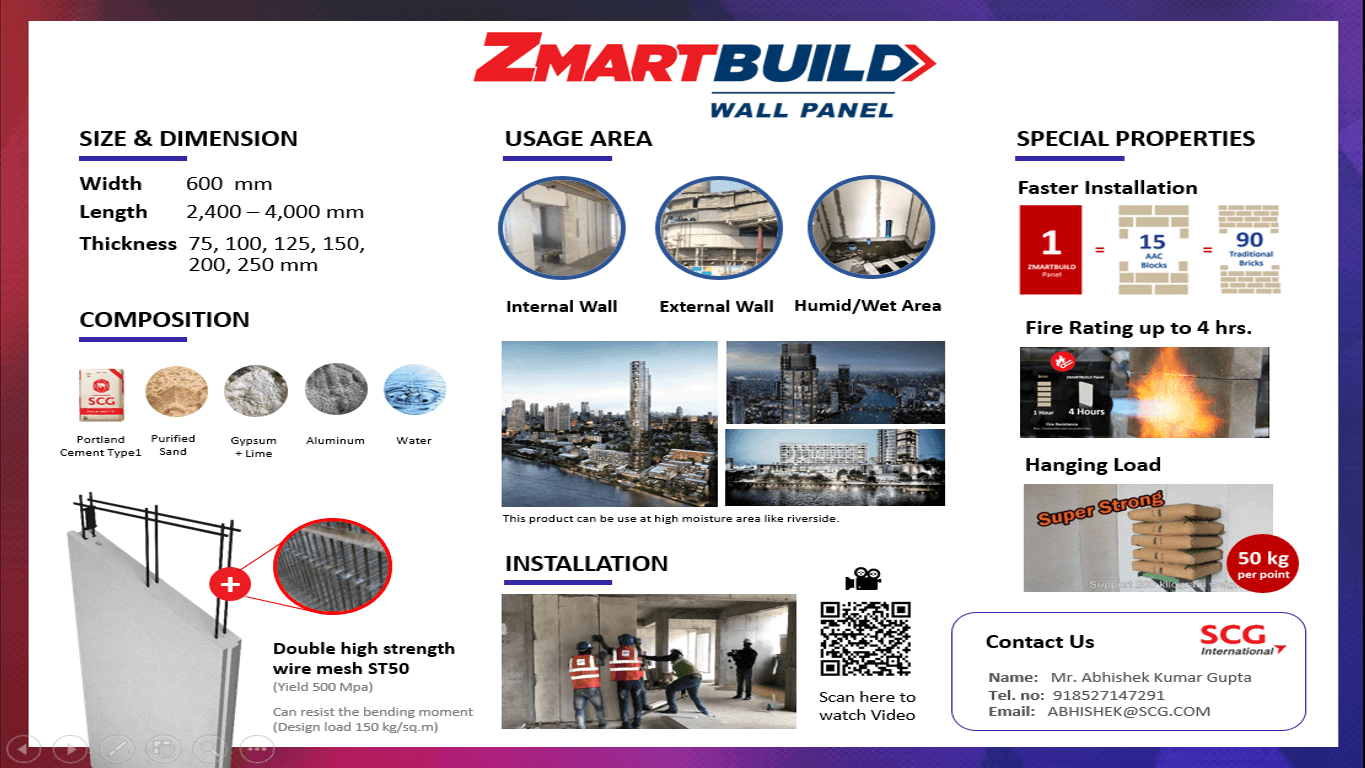

SCG Group from Thailand introduces – Zmartbuild Wall Panel to India market. It is the 3rd generation of wall material which helps project to save overall cost, faster construction by 4 times than traditional AAC Block wall and reduce chances of wall crack due to shrinkage. Our Zmartbuild Wall Panel is trusted quality product which is proved by over 3,068 projects around the world including mega projects in Thailand like Siam Paragon, Luxury shopping mall and Terminal 21 Korat, etc.

SCG – Zmartbuild Wall Panel compliance the Sever duty test according to BS 5234 Part 2 – 1992 from AIT – Asian Institute of Technology. This is a suitable product to construct a wall from domestic to heavy industrial applications. And the partition work of other types of buildings which requires partition grade at the level lower than the residential buildings.

So we are pleased to be the trustworthy manufacture who brings the good quality and innovative products to India market. Do not hesitate to contact us if you need more information.