- Email: info@zmartbuild.com

- Tel. +6681-848-0870

- Mon-Fri 9:00-18:00

ZMARTBUILD Panel - 4X Faster than AAC Blocks

ZMARTBUILD Wall Panel

ZMARTBUILD Wall Panel is the future of AAC Blocks as it is bigger in size, allowing you to build faster and get more advantages such as improved performance, cost & time saving, project efficiency, and carpet area.

- Lightweight and Easy to Work

- Fast Installation and Clean Site

- Thermal, Sound and Fire Resistance

- Environment-Friendly and Energy Saving

Key Documents & Design Files

Features & Benefits

SUPER SPEED

It is 4 times faster than AAC Blocks and can easily be installed by groove and tongue panels. General installers can install the ZMARTBUILD Wall Panel more than 10 sqm/man/day.

STRONG & DURABLE

Reinforced with preventive corrosion steel, it is durable and wind-resistant. With no knocking sound, this wall panel can hang 50 kg per point by expansion fixing.

SAVE BUDGET & EARN MORE

It reduces working time and transportation cost as it is lightweight (70 kg/m2). Furthermore, ZMARTBUILD Wall Panel has better heat insulation than AAC panel (K=0.115 w/mk.) to save energy.

GOOD FIRE RESISTANCE

It offers excellent fire resistance as ZMARTBUILD Wall Panel is made with non-combustible material and can protect it from fire for 4 hours.

ENVIRONMENTAL FRIENDLY

ZMARTBUILD Wall Panel is non-toxic as it is made with environment-friendly material. The use of natural components helps reduce waste as well.

Product Option

Product Size

| Size W x L x H (cm.) | Weight Kg./m2 | Packaging Pcs/Pallet |

|---|---|---|

| 60 x 300 x 7.5 | 70 | 10 |

| 60 x 300 x 10 | 100 | 7 |

Special Property

ZMARTBUILD Wall Panels (also known as Q-CON in Thailand) are lightweight, steel reinforced, with groove & tongue panels that can be easily installed by your regular on-site installers. They are suitable to be used as both external and internal walls.

ZMARTBUILD Wall Panel TECHNOLOGY

Thermal resistance and energy saving

Reducing the reliance on heating and cooling appliances.

Sound resistance

Reduced sound transmission between rooms and noise penetration from external sources.

Non toxic

Made with environment-friendly material to make it non-toxic.

Easy to use

ZMARTBUILD Wall Panel is lightweight making it easy to move, easy to transport and easy to install.

Reduce construction time

60% faster than masonry using semi skilled trades.

Light Weight

Made lightweight so that it is easy to use.

Long Life

Not easy to wear off and is durable to all weather conditions.

Precision

An established quality control program allows builders to achieve optimal structural performance.

Less wastage

ZMARTBUILD Wall Panels are manufactured in a range of sizes to suit your needs, resulting in less wastage.

ZMARTBUILD Wall Panel Special Property Detail

Quality Product Approval

ZMARTBUILD Panel Passed BS5234 Standard Guaranteed … Trusted Partition for your project!!!

- It is up to 2.5 times lighter to help reduce the structure load. ZMARTBUILD Wall Panel is 70 kg/sq.m. while brick wall is approximately 180 kg./sq.m.

- Constant standard of compressive strength > 40 kg/sq.m. due to controllable production process.

- Ensure your safety with excellent fire resistance. ZMARTBUILD Wall Panels can stay fire resistant for 4 hours while bricks can only stay for 2 hours.

- 10 times less thermal conductivity than bricks. ZMARTBUILD Wall Panel makes you feel cooler when you stay at home as there is less thermal conductivity at 0.115 W/mk., compared to normal brick that is at 1.12-1.14 W/mk.

Super Speed Install

ZMARTBUILD Wall Panel can help you to finish the job 3 times faster than brick & mortar. It can also be easily installed by groove and tongue panel.

- 60% faster than masonry using semi-skilled trades.

- Panel is larger in size than brick and AAC blocks that bring to fewer joints.

- Installer capacity is up to 10 sqm/man/day.

- No special skill is required to install.

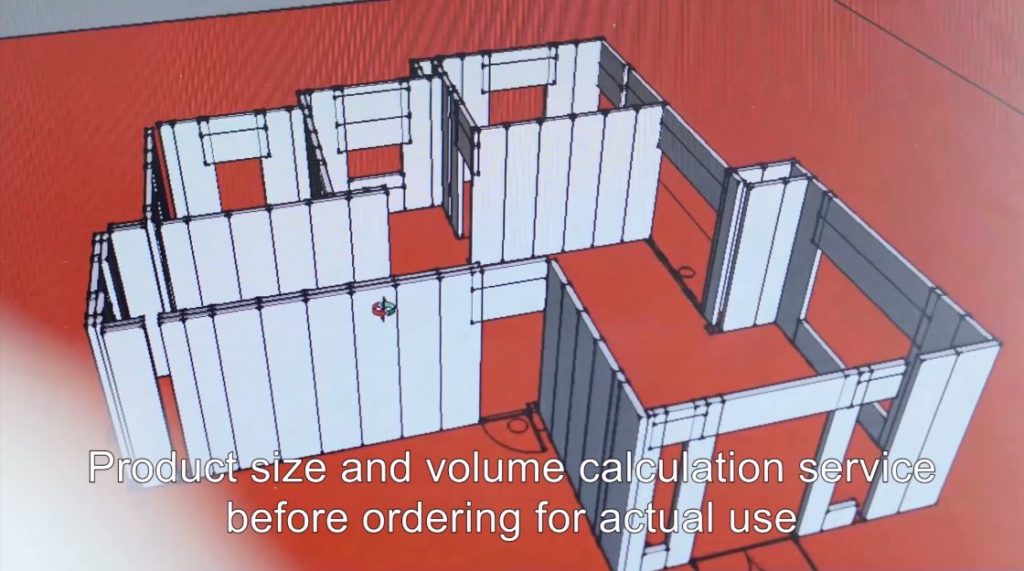

Several sizes to match your wall area

ZMARTBUILD Wall Panel is steel reinforced starting from 7.5 cm. thickness and in lengths of 1.50 – 4.0 m. and width of 0.6 – 3.0 m.

Dimension, Weight and Packaging:

W x L x H (cm.) Weight Packaging

60x300x7.5 70 kg/sq.m. 10 Pcs/Pallet

60x300x10 100 kg/sq.m. 7 Pcs/Pallet

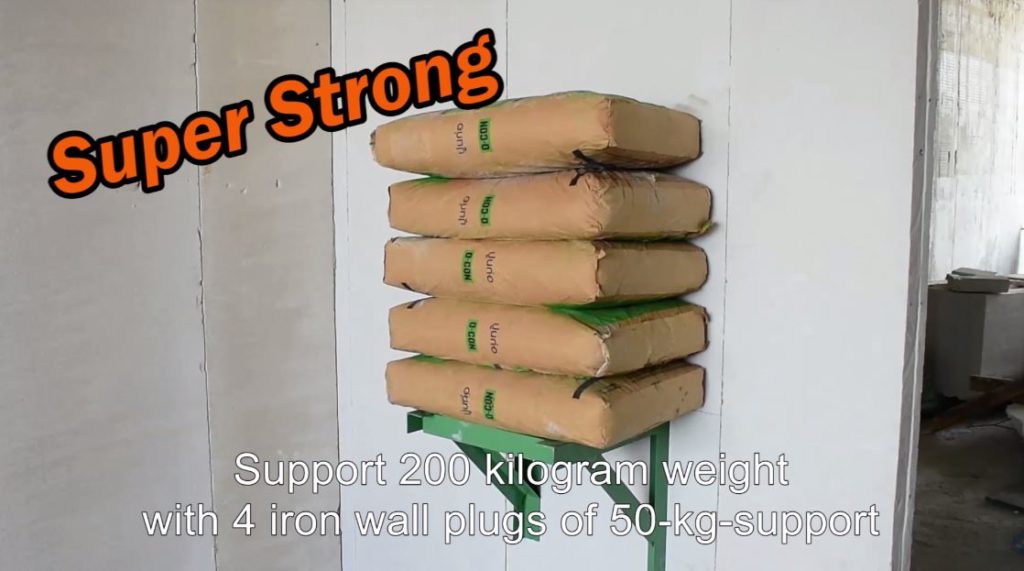

Sturdy and strong wall panels

ZMART BUILD Wall Panels are reinforced with preventive corrosion steel making it durable against strong winds and heavy loads.

- Not fragile: Specially coated steel to prevent corrosion and provide maximum durability.

- No Knocking Sound: This property is the same as AAC Blocks as it was developed from AAC Blocks.

- Durability: It has high wind load resistance and doesn’t require any special maintenance

Load Bearing Wall: Supports 200kg weight with just 4 iron wall plugs of 50 kg support.

Enhance your safety life by selecting fire-retardant material

ZMARTBUILD Wall Panel is known for its highly fire-resistant properties. With fire resistance capabilities for upto 4 hours, it can protect you better in case of a fire-risk.

- Fire protection for up to 4 hours

- Non-combustible

- Property of Autoclaved Lightweight Concrete (ALC)

Save more budget, Get more money

As an Autoclaved Lightweight Concrete (ALC), ZMARTBUILD Wall Panel can save budget costsand energy consumption.

- Reduced working time due to faster and easier installation.

- Reduced transportation cost as it is lightweight (70 kg/m2 ) and ¼ the weight of traditional concrete.

- Good heat insulation (K=0.115 w/mk.) like the ALC Block that help reduce the reliance on heating and cooling appliances like ALC Block that reducing the reliance on heating and cooling appliances

Environment-friendly product

ZMARTBUILD Wall Panel is manufactured in a range of sizes to suit your needs, resulting in less wastage. Moreover, it is made from completely natural materials which do not cause pollution..

- Made from non-toxic components.

- Less mess on-site and less clean-up at completion of construction.

Installation Guideline

Easy installation by your normal on-site installers … Everyone can do it!

Pre-Installation

1. Check sizes and quantities of ZMARTBUILD Wall Panel.

2. Check layout and construction drawing.

Check tools and equipment.

3. Check tools and equipment.

Installation Steps

1. Clean and mark the wall alignment. Clean the floor and ceiling to rid it of any dust or dirt before drawing the chalk tape line.

2. Clean ZMARTBUILD Wall Panel and move it to the marked point.

3. Mix thin-bed mortar and apply it on the structure. Apply the mixed thin bed mortar on the column structure for increased adhesion between the ZMARTBUILD Wall Panel and the structure.

4. Lift the wall panel and push it to attach the column.

5. Insert a foam sheet between the floor and the top of the panel. Foam sheets prevent the wall from cracking.

6. Use a lever to lift ZMARTBUILD Wall Panel until the top of the panel reaches the upper floor. Then insert a wood wedge under the panel.

7. Use the steel angle to fasten the panel on the floors on both upper and lower side of the panel by using steel plugs and screws.

8. Apply a thin-bed of mortar on the side of the first panel then lift the next wall panel to attach and do the same as the previous steps.

9. Continue to install wall panels until the gap can be closed with the last panel.

10. Measure the gap and cut the last panel to fit, then install it in place.

11. Fill the gap under the panels with sand-cement mortar.

12. Fill all the gaps between each panel with thin-bed mortar. Wait until the mortar dries, then rub with sandpaper #400.

13. Finish all the gaps again with a skim coat, then rub with sandpaper #200.

14. The ZMARTBUILD Wall Panel installation is done. You can also paint the surface according to your requirement, if needed.

Application Guideline

- Living Room

- Commercial/Department Store

- Office

- High Rise Building

- Hotel

- Factory

- Warehouse

- Green Building

Case Study

CENTRAL PATTANA PUBLIC COMPANY LIMITED

THE LARGEST RETAIL PROPERTY DEVELOPMENT COMPANY IN THAILAND

Central Pattana Public Company Limited or CPN is the owner and operates many shopping centers under three brands; CentralWorld, CentralPlaza, and CentralFestival.

It is our pleasure to partner with CPN and provide ZMARTBUILD Wall Panels to many shopping centers such as CentralWorld, CentralPlaza Chaengwattana, CentralPlaza Lardprao and CentralPlaza Chonburi.

What makes our leader company confident in ZMARTBUILD is the super speed installation process. The ZMARTBUILD Wall Panel installation is 4 times faster than brick and mortar.

- 60% faster than masonry using semi-skilled traders.

- The panel is larger in size than bricks and AAC blocks, resulting in fewer joints.

- It can be easily installed with groove and tongue panels.

CPN can not only save time using ZMARTBUILD Wall Panel, it also has other hidden advantages like:

- Cost-saving because of faster installation and completion of projects: Save money from labor, equipment rental, space rental, waste disposal, etc.

- The lightweight panel saves materials: Lighter superstructure (beam column), smaller footing and pile saving.

- Saves energy because of less thermal conductivity: With a reduced thermal conductivity, you can save money with the reduced use of air conditioners.

- Quick completion of the project will result in better finances: You can receive better loan interests from banks and also start the business ahead of schedule.

Reference Site

Noppakao Warehouse

Thailand

Lazio Condominium

Thailand

Terminal 21 Korat

Thailand

Siam Paragon

Thailand

The Win

Thailand

The Cube 2 Condominium

Thailand

The Room Condominium

Thailand

The Diamond Condominium

Thailand

The Cube Condominium

Thailand

Miami Project

Thailand

Zensation Condominium

Thailand

Jakpaisal Residential

Thailand

Singha Factory

Thailand

Ratdawan

Thailand

The Modular House

Thailand

Specification & Standard

| Product Property | Wall Panel | Standard |

|---|---|---|

| Dry Density | 550-650 Kg/m3 | IS – 2185 (Part III) |

| Working Density | 600-700 Kg/m3 | |

| Wind Load | 50-180 Kg/m2 | |

| Compressive Strength | >4 N/mm2 | IS2185(partIII) |

| Water Absorption | <33% | by mass |

| Fire Rating | Up to 4 hr | 100mm. thickness wall panel / BS476 Part 20 and 22 :1987 |

| Thermal Conductivity (k) | 0.115 W/mk | |

| Sound Insulation (STC) | 38 - 43 dB | |

| Reinforce steel tensile strength | > 500 N/mm2 | |

| Weight | 70 kg/m2 | 100 mm thickness wall panel |

Installation

Related Documents

Customer Service

Contact Us

Tel./Whatsapp +6681-848-0870

Email: info@zmartbuild.com